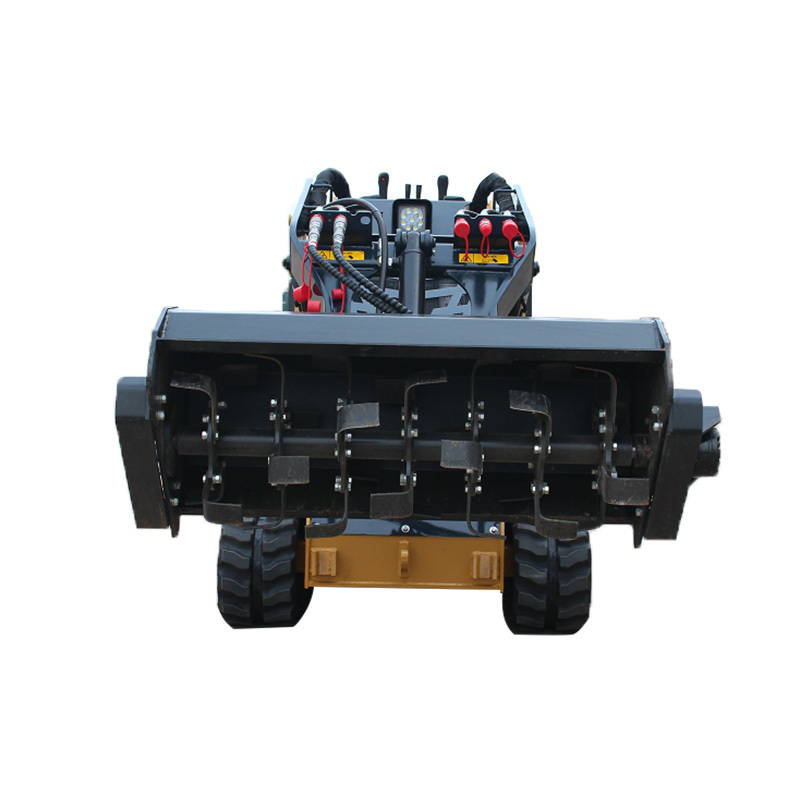

Cement mixing bucket

Classification :

Attachments

- Cement mixing bucket Commodity name:

- 691mm Overall length

- 1325mm Overall width

- 616mm Overall height

Categorisation:

Attachments

Short mixing time for conventional materials: Traditional mixing buckets have a capacity of 1 cubic meter.

Keywords:

Attachments

E-mail:sales@cnmattson.com

Cement mixing bucket

The characteristics of cement mixing bucket mainly include:

Short mixing time for conventional materials: Traditional mixing buckets have a capacity of 1 cubic meter.

Adjustable blades: maintenance free.

Fully enclosed gearbox: to prevent sediment from entering the gearbox and damaging it.

Bidirectional mixing: Mixing evenly, with a wide range of applications, suitable for various occasions and not easily overturned.

Two driving motors: with sufficient power, the loader has 55 horsepower and can only drive the mixing bucket with a torque of 3.5 τ or above.

No butter added: Gear oil should be added. The bucket tooth structure adopts a combination welding type bucket tooth, which is reasonable in structure, easy to replace, and cost-effective. High tech welding is used to avoid welding stress in high stress areas, reduce welding deformation, and improve construction.

Previous

Next

Previous

Trencher

Previous

Factory

Related Products

Skid Steer Loader

Wheel Skid Steer Loader

-

ML525W Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525W Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525W Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525W Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525W Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525W Tire Mini Skid Steer Loader

The operation of the skid steer loader is relatively simple, with a reasonable layout of the operating lever and console, allowing the operator to quickly grasp and operate it.

Track Skid Steer Loader

-

ML530Y Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML530Y Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML530Y Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML530Y Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525Y Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525Y Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML550TS Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML550TS Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525X Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML550X Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML550TS Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML530Y Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525Y Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525Y Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525N Skid steer loader grapple

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525N Skid steer loader digger

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525N Skid steer loader auger

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525N Skid steer loader 4 in 1 bucket

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525N Skid steer loader 3 in 1 bucket

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525N Skid steer loader

It is suitable for workplaces that require frequent transitions and can quickly reach the target location.

-

ML525 Skid steer loader

It can be used for various operations such as loading, unloading, handling, leveling, flipping, etc., with strong adaptability and flexibility.

-

ML525L Skid steer loader

It does not require complex operational skills, reducing operational difficulty and training costs.

-

ML530 Skid steer loader

Hydraulic systems are relatively energy-efficient, as they transmit power through fluids to reduce energy loss.

-

ML550 Skid steer loader

Compared with some large loaders, the carrying capacity of skid steer loaders is relatively small.

Remote Control Skid Steer

Attachments

-

Roller

The roller is suitable for various compaction operations due to the gravity of the machinery itself, causing permanent deformation and compaction of the compacted layer.

-

Rotary Tiller

It is important to use and adjust the rotary tiller correctly to maintain its good technical condition and ensure the quality of cultivation.

-

Wood chipper

The wood crusher can not only crush various types of wood, but also include hardwood, cork, particleboard, plywood, etc.

-

Loosener

The soil compactor is a replaceable working device with crushing and loosening functions.

-

Lightweight bucket

Lightweight buckets are suitable for excavating low impact, low wear materials such as soil, loam, and clay.

-

Sweeper Bucket

The enclosed sweeper is highly sought after by various industries due to its environmentally friendly characteristics and is widely used.

-

Grapple bucket

Wide applicability: Not only suitable for wood handling, but also for handling other cylindrical goods such as PVC plastic pipes.

-

Snow shovel

A snow shovel is an iron shovel used for pushing snow, which is wider and taller than a general iron shovel.

-

Cement mixing bucket

Short mixing time for conventional materials: Traditional mixing buckets have a capacity of 1 cubic meter.

-

Trencher

It mainly consists of a power system, a deceleration system, a chain transmission system, and a soil separation system.

-

Rock bucket

The main characteristics of rock bucket are high strength, strong wear resistance, adaptability to harsh working environments, and improved work efficiency.

-

Pitchfork

The advantages of speed and cost-effectiveness provide the motivation to obtain a wide range of work.

FAQ

How many decking production line do you have ?

We have multiple production lines that can meet your various needs.

Where is your market located?

Sold to major cities across the country and international markets (Southeast Asia, Middle East, Europe, America, etc.).

Can you send the product to my country?

Certainly. If you don't have your own freight forwarder, we can provide assistance for you.

Can I visit your factory?

Welcome to our factory. Please contact us first. With your schedule, we will provide you with the necessary services.

Do you accept small orders?

Don't worry. Please feel free to contact us at any time. In order to obtain more orders and provide our customers with more conveners, we accept small orders.

When can I get the quotation?

We usually provide you with a quotation within 24 hours after receiving your inquiry. If you urgently need a quote. Please call us or let us know in your email so that we can prioritize your inquiry.

What about the lead time for mass production?

Usually takes 15-30 days, depending on the quantity and project.

sales@cnmattson.com

sales@cnmattson.com